Language: 日本語 | English

Language: 日本語 | English

Come to us for light, small, narrow and difficult leaf springs, from testing to mass production!

If you have a die but are having trouble with press stamping, then consult with us.

We can offer a wide range of round-shaped products! Our company can do both curling and drawing! We'll propose the optimal production method!

C1720R-HM Small-Diameter Curling Processing (Progressive Stamping, Continuous Winding)

High-Precision Processing of Complex Shapes Using Multi-Forming Machines

Contact Bushing – Phosphor Bronze + Silver, Progressive Pressing & Riveting

![Replacing Machining with Press Processing – [Thick Plate Pressing]](https://en.nc-net.com/up/library/1302/70640/a54c156afbb8b515ad34a4730a1736354678a4e5.jpg)

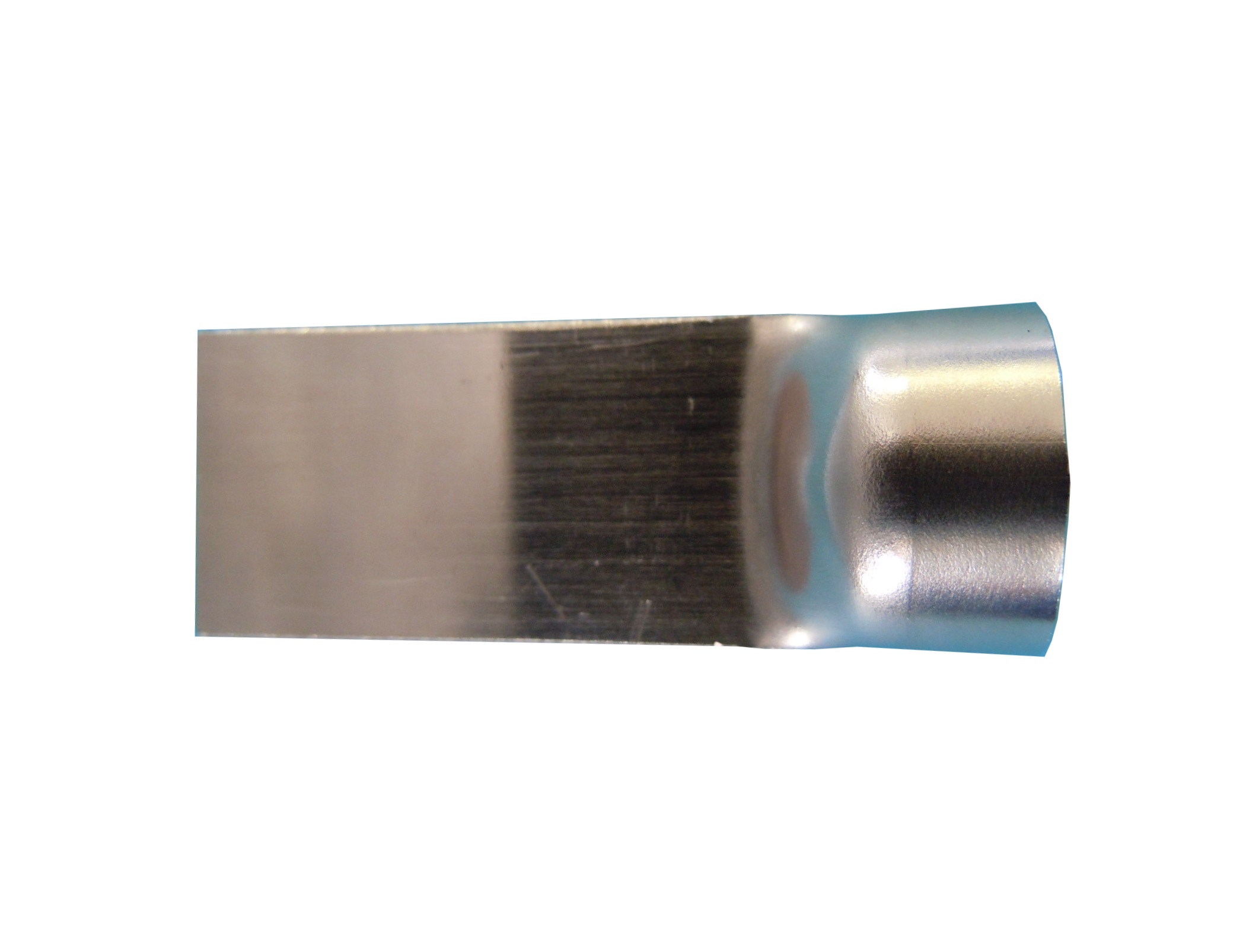

Replacing Machining with Press Processing – [Thick Plate Pressing]

![Replacing Machining with Press Processing – [Thick Plate Pressing]](https://en.nc-net.com/up/library/1302/70640/a54c156afbb8b515ad34a4730a1736354678a4e5.jpg)

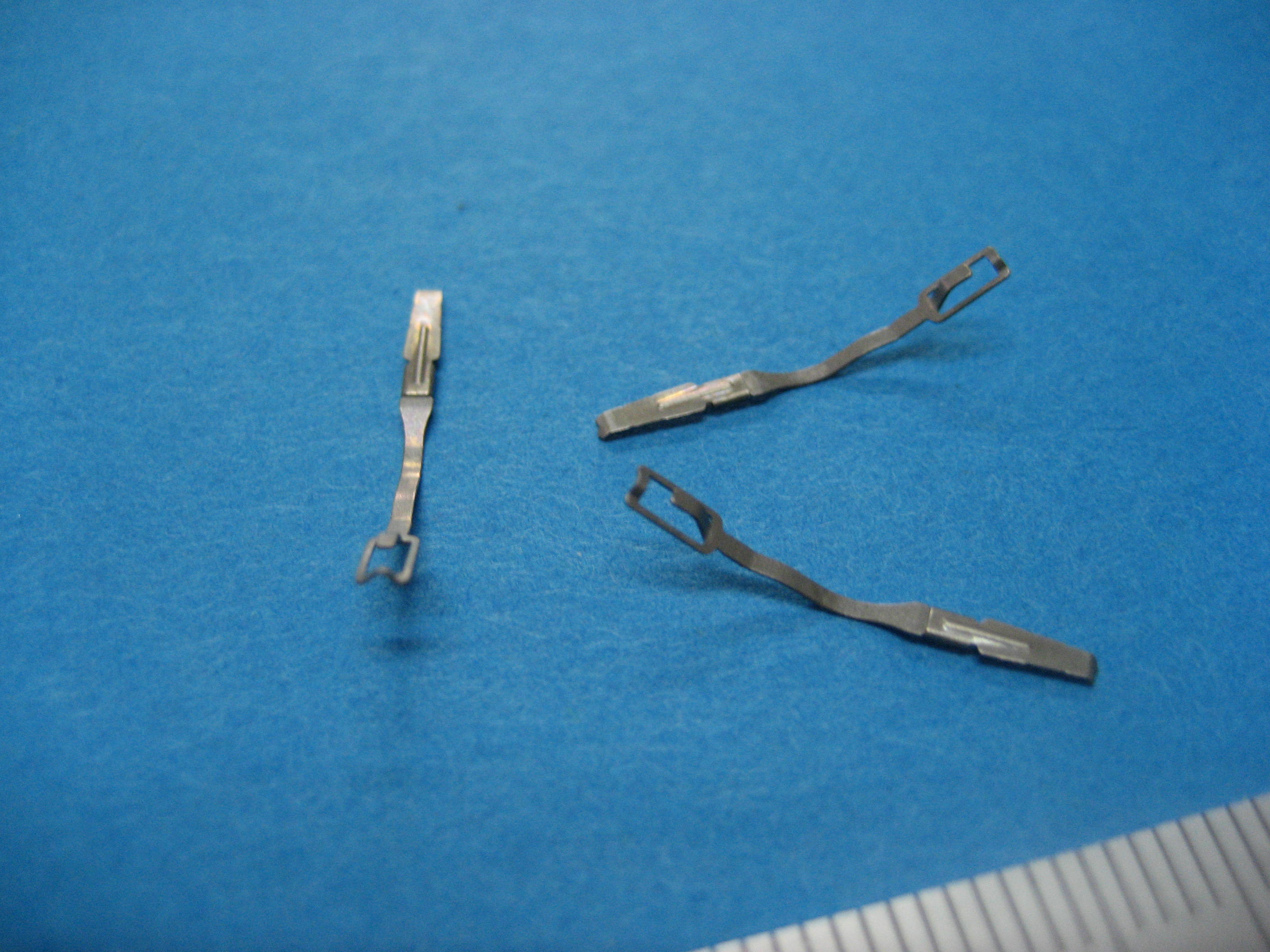

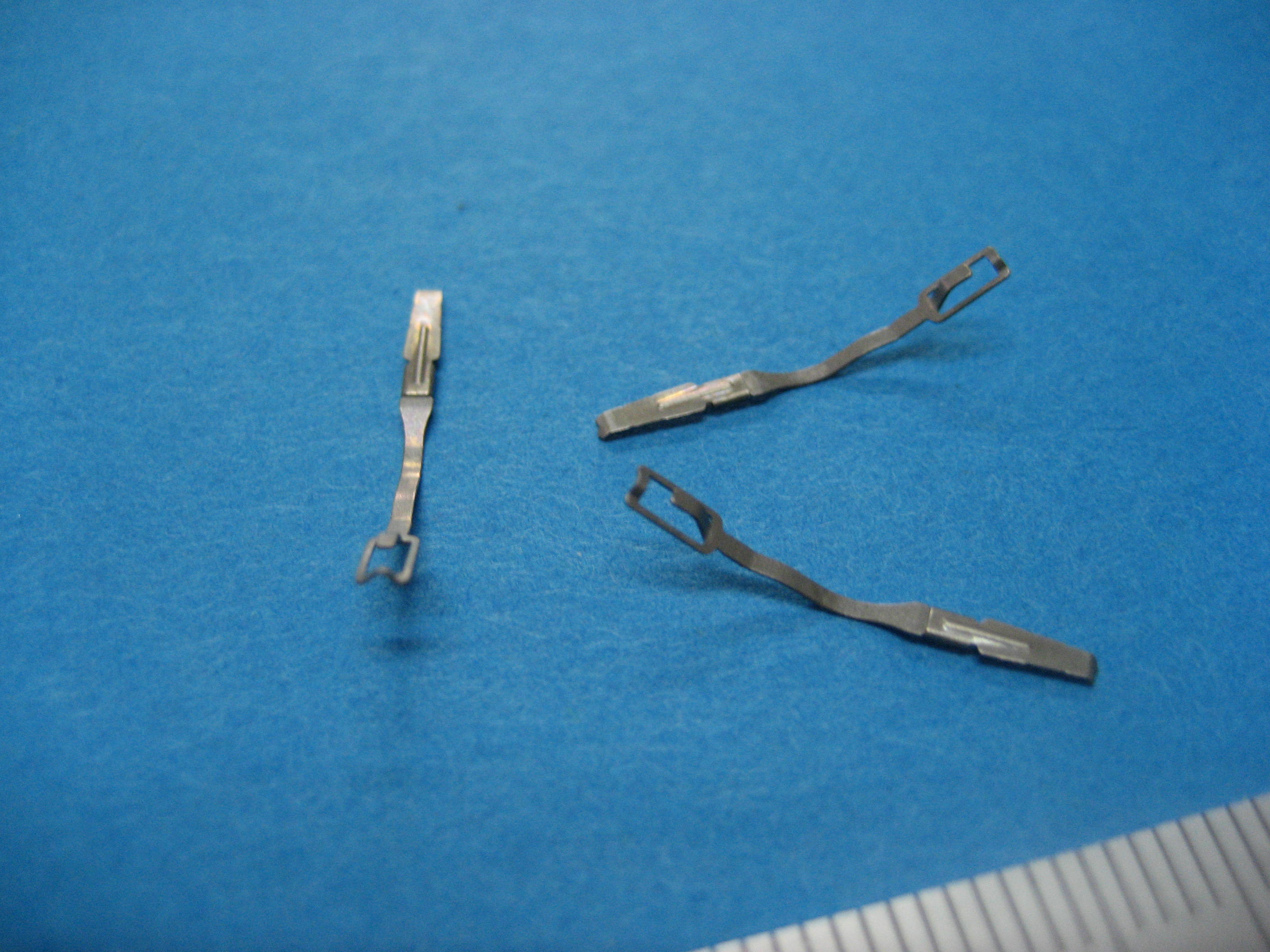

Come to us for fine, thin, small, narrow and complex plate springs when you have no time to spare between testing and mass production!

High-Precision Stainless Steel Plate Springs for Control Cable Fastening

Leaf Spring – Brass + Beryllium Copper, Progressive Pressing & Riveting (4 Points)

Leaf Spring – Brass + Beryllium Copper, Progressive Pressing & Riveting (2 Points)

Bracket (Motor Case) – Stainless Steel SUS, Progressive Pressing & Riveting

We make everything from plates to three-dimensional objects. We perform cold forging on shapes that aren't possible with cutting!

Precision Processing of Plate Springs, Wire Springs, and Metal Bending/Punching

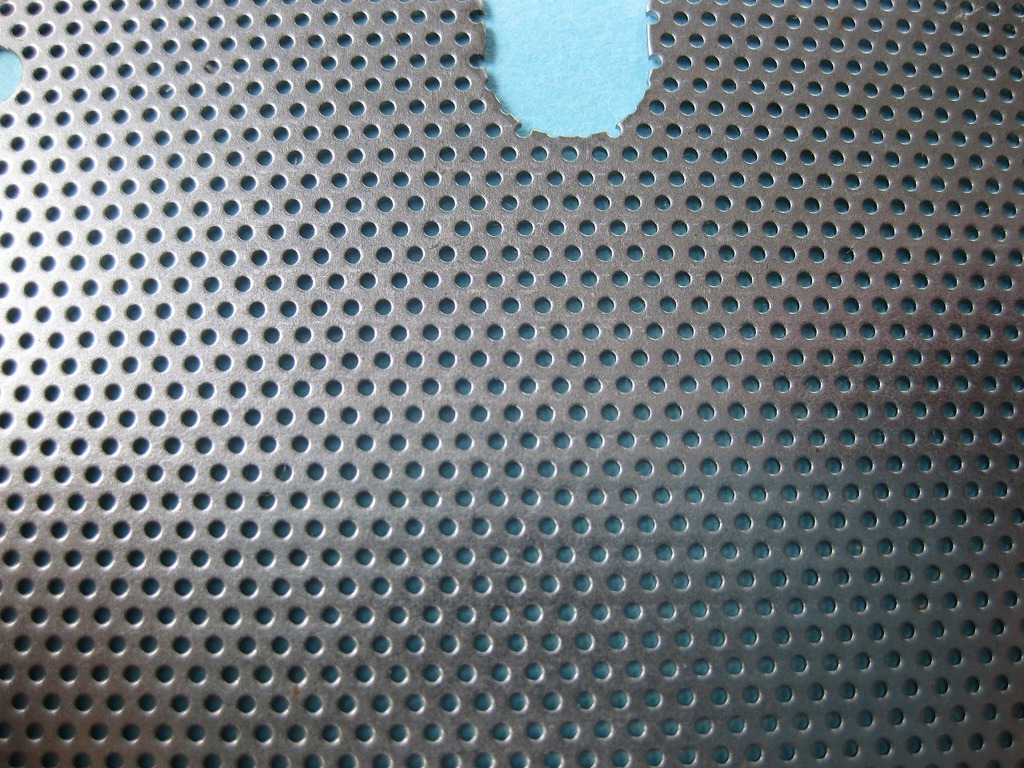

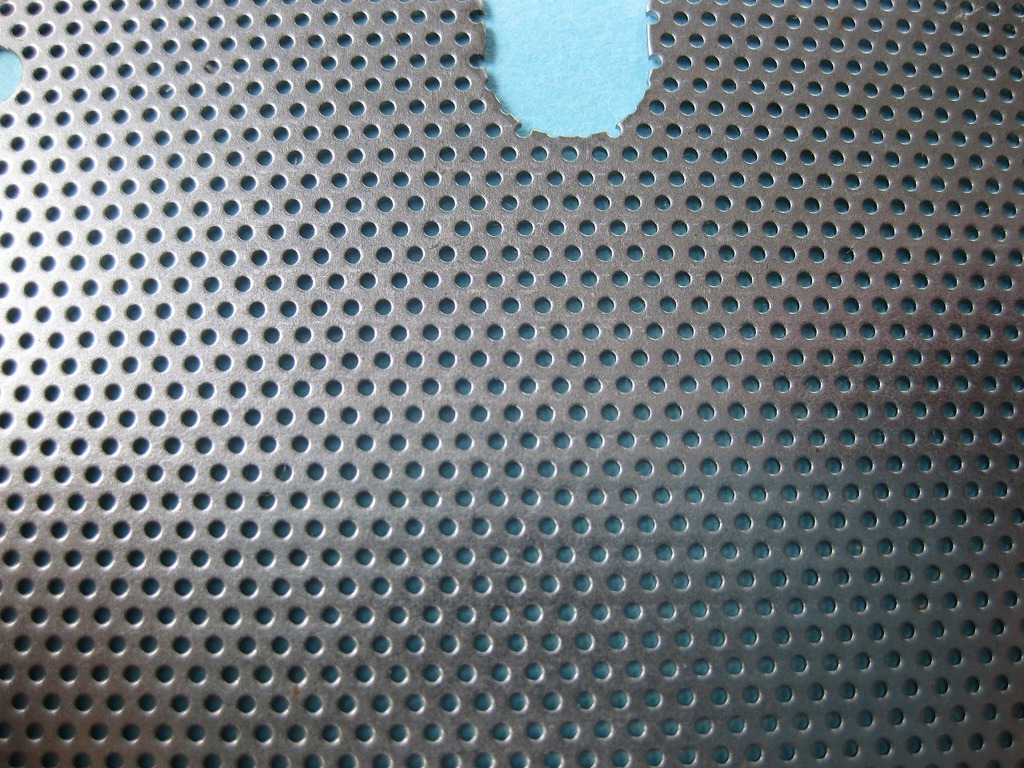

Progressive Die Method for Press Processing Punching Plates

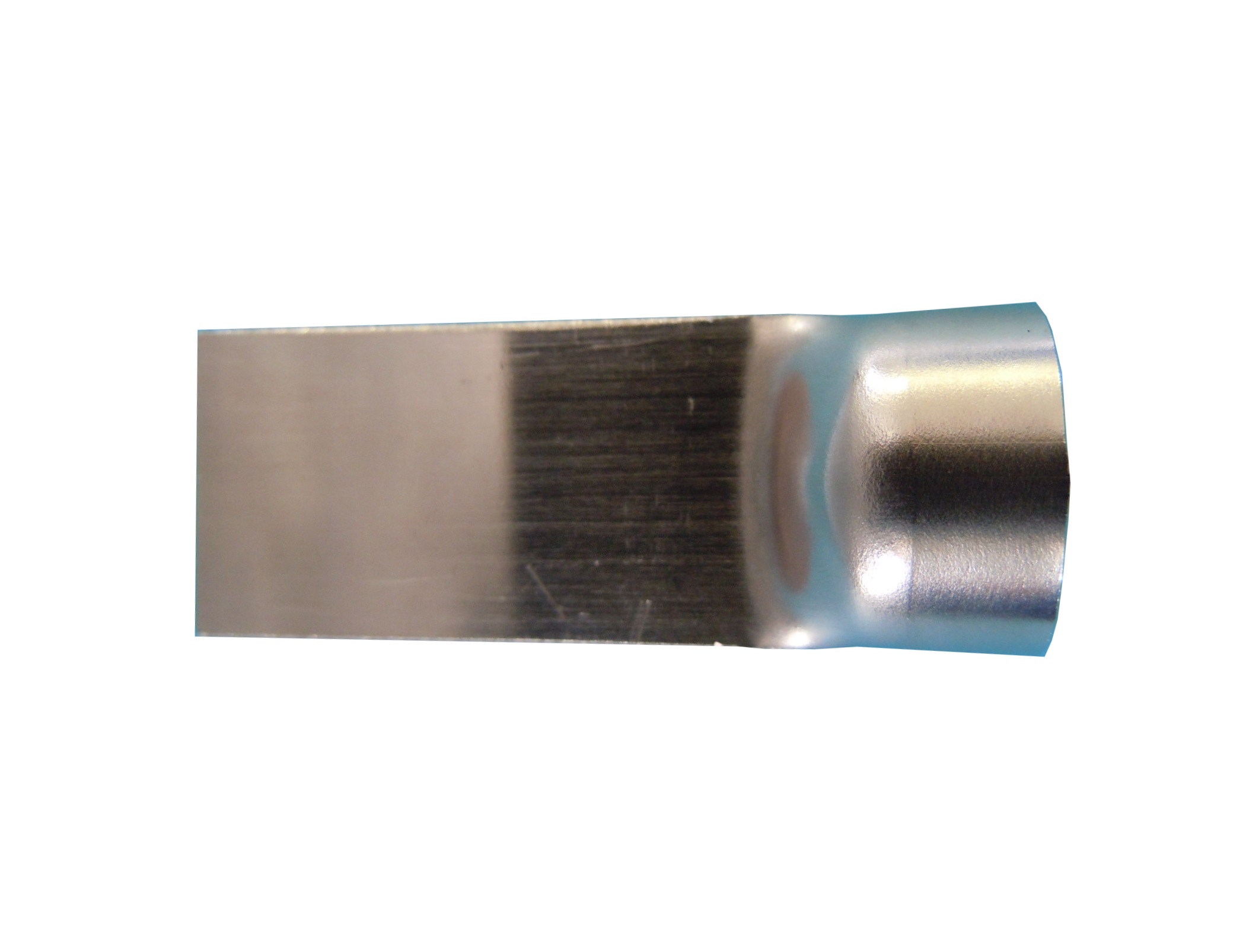

The round shaped metal fittings applied Splitting (Warisaki) processing technology